We produce high-quality metal powders for Additive Manufacturing, optimized for consistent flowability and repeatable build performance.

Our powders enable the production of complex, high-strength components for aerospace, medical, and industrial applications.

(Similar to Metco Powders)

Our self-fluxing powders are designed for spray-and-fuse applications, delivering dense, metallurgically bonded coatings with outstanding resistance to wear, abrasion, and corrosion.

These powders are suitable for heavy-duty industrial and engineering applications requiring durable surface protection.

Versatile powders for spray-and-fuse applications, delivering dense, metallurgically bonded coatings for extreme wear and corrosion resistance.

Specialized hardphase additives and carbide blends designed to maximize coating resistance to severe abrasion, erosion, and corrosion.

(Similar to Metco Powders)

Lattice Aerospace supplies self-bonding and superalloy powders for thermal spray applications, offering excellent adhesion, wear resistance, and corrosion protection for critical components.

These powders are widely used for component repair, surface protection, and life extension in extreme operating environments.

Self-bonding superalloy powders for robust component repair and superior resistance to extreme heat and corrosion.

(Similar to Wall Colmonoy Powders)

We offer nickel-based and cobalt-based brazing filler metal powders engineered for strong joints and high-temperature performance in aerospace and industrial assemblies.

These materials ensure reliable bonding in critical, high-stress environments.

High-performance brazing powders delivering superior joint strength and heat resistance for critical aerospace and industrial applications.

(Similar to Stellite Powders)

Our cobalt-based superalloy powders for Plasma Transferred Arc applications provide exceptional resistance to heat, wear, and corrosion.

They are ideal for hardfacing and component reinforcement in severe service conditions.

Premium cobalt-based superalloys designed for PTA hardfacing, delivering exceptional resistance to heat, corrosion, and wear in severe industrial environments.

Aerospace & Defence

Aerospace & Defence Medical

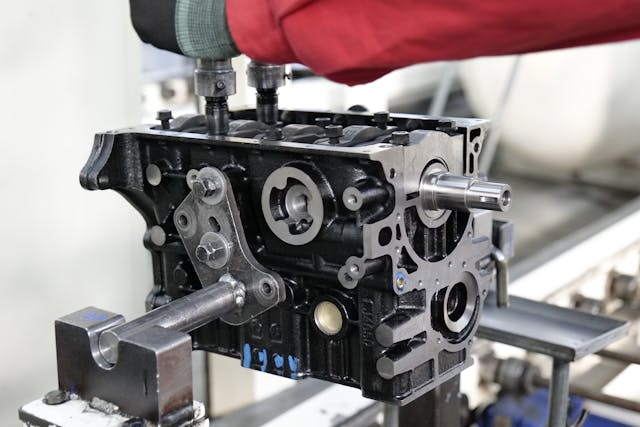

Medical Automotive

Automotive Energy

Energy