At Lattice Aerospace, our technology is built to meet the most demanding requirements of high-performance industries. We combine advanced manufacturing processes with deep materials expertise to deliver metal powders with exceptional consistency, purity, and performance.

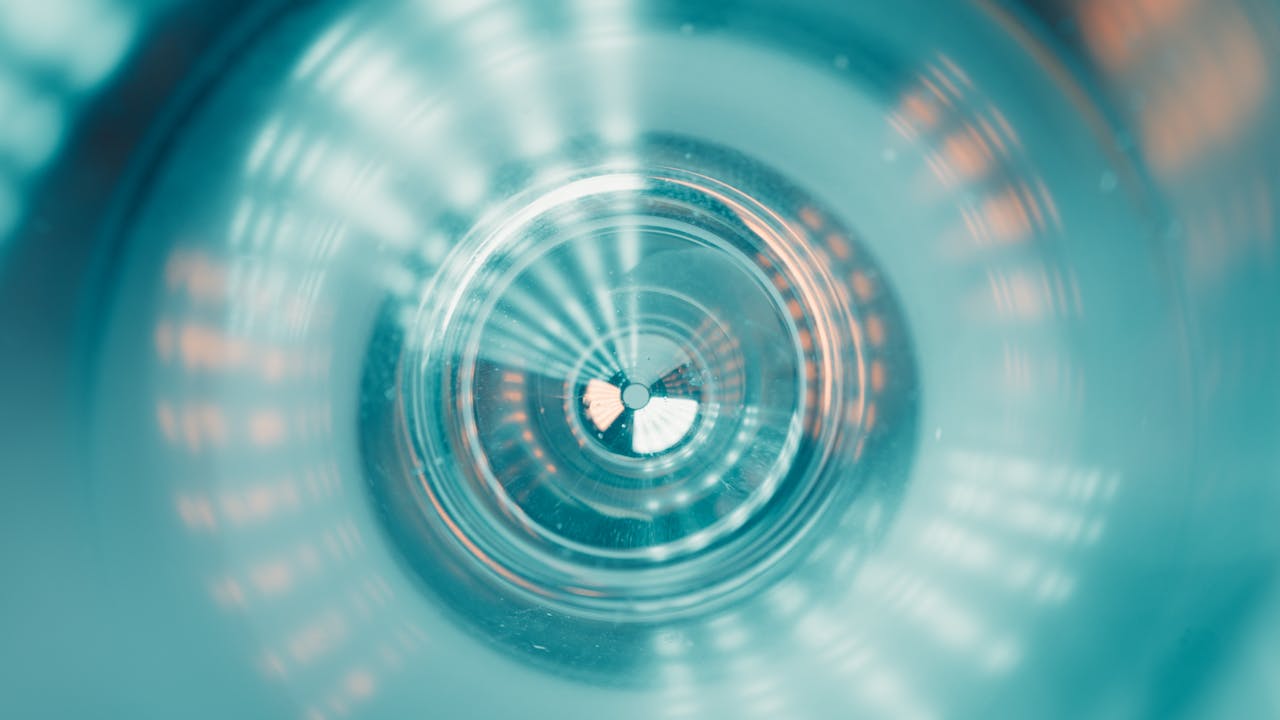

We utilize Vacuum Induction Melted Inert Gas Atomization to produce high-quality metal powders. By melting and atomizing metals in a controlled vacuum and inert environment, we achieve superior cleanliness, minimal contamination, and precise control over particle characteristics.

Our process consistently achieves oxygen levels below 100 ppm, making our powders ideal for critical applications in aerospace, defence, and additive manufacturing where material integrity and mechanical performance are essential.

Lattice Aerospace powders are engineered for high sphericity and satellite-free morphology, ensuring excellent flowability, uniform spreading, and high packing density. This translates into improved process stability and repeatable part quality.

We offer customized particle size distributions tailored to specific manufacturing methods, including additive manufacturing, thermal spraying, and brazing. Typical size ranges include 15–45 µm and 45–105 µm, with additional options available on request.

With an annual capacity of 500 MT and flexible batch sizes of 200 kg and 500 kg, we support both high-volume production and specialized development programs without compromising quality or consistency.

Every stage of our production process is guided by strict quality controls and continuous monitoring. Our focus on process stability and material traceability ensures reliable performance across every batch we deliver.